Services

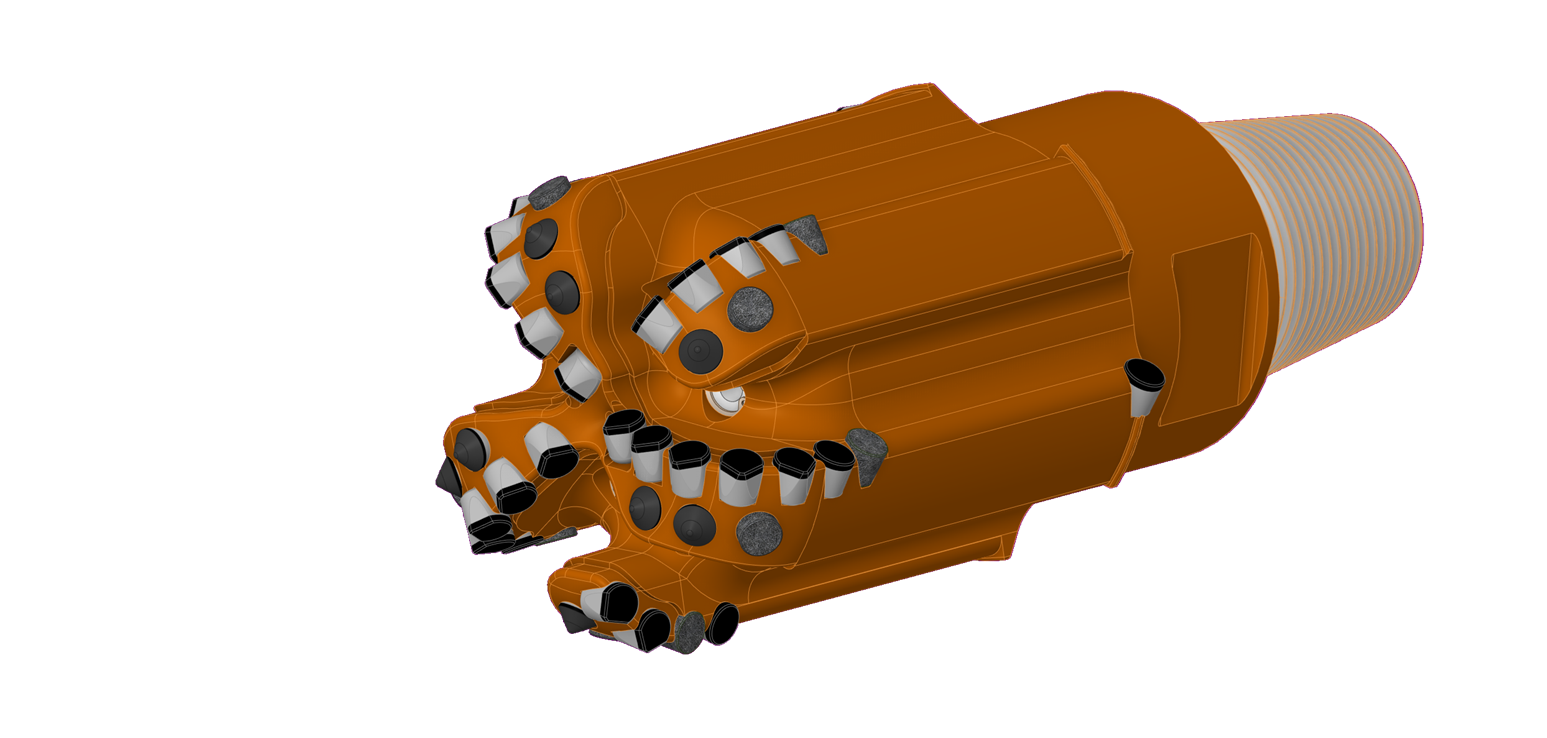

PDC Drill Bits

The drill bit is a critical component of the drilling borehole assembly. It defines and influences how safe, efficient, and economical drilling can be.

To ensure the success of drilling operations, it is critical to select the right bit for the right application.

Drill bit selection is a complex process, as a lot of variables need to be accounted for: lithology, trajectory, borehole assembly, length of the interval to drill, drilling mud, rig specification and limitations, bit design features, and properties.

This makes bit design selection a time-consuming, highly specialized, and often subjective exercise.

High specification bits are expensive and when incorrectly selected will not deliver the desired performance. This makes PDC bits mostly prohibitive in budget-sensitive but challenging applications, like geothermal drilling.

ZerdaLab is reducing the cost of high specification drill bits while improving the speed and quality of bit selection for the customer’s application.

Advantages

High Specification Components

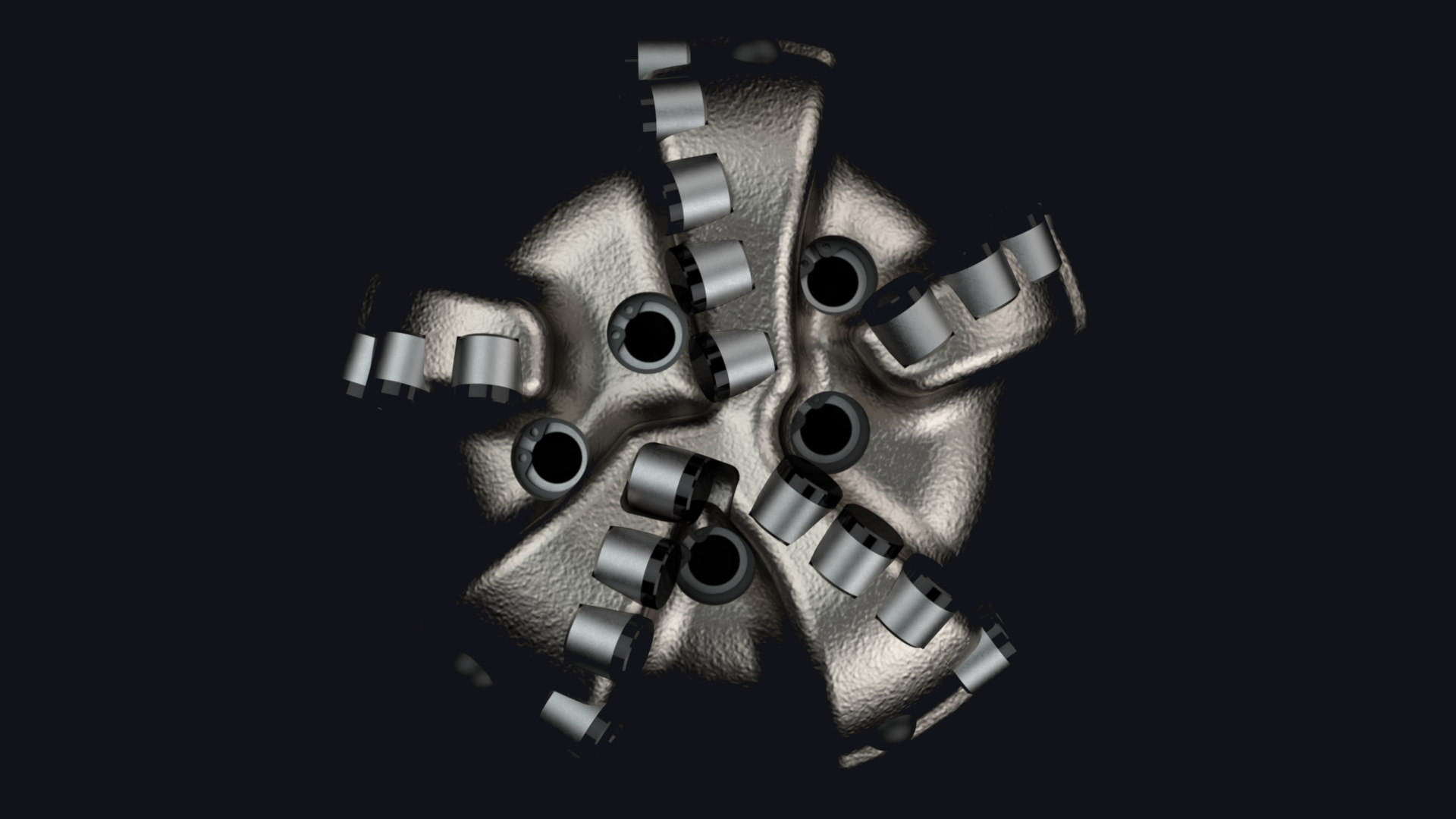

- Cutters

- Hardfacing

- Secondary Components

- API Compliant

Simplified for Manufacturing

- Unified cutter size

- Reduced number of unique components

- Reduced number of critical dimensions

- Option for fixed TFA - ports vs nozzles

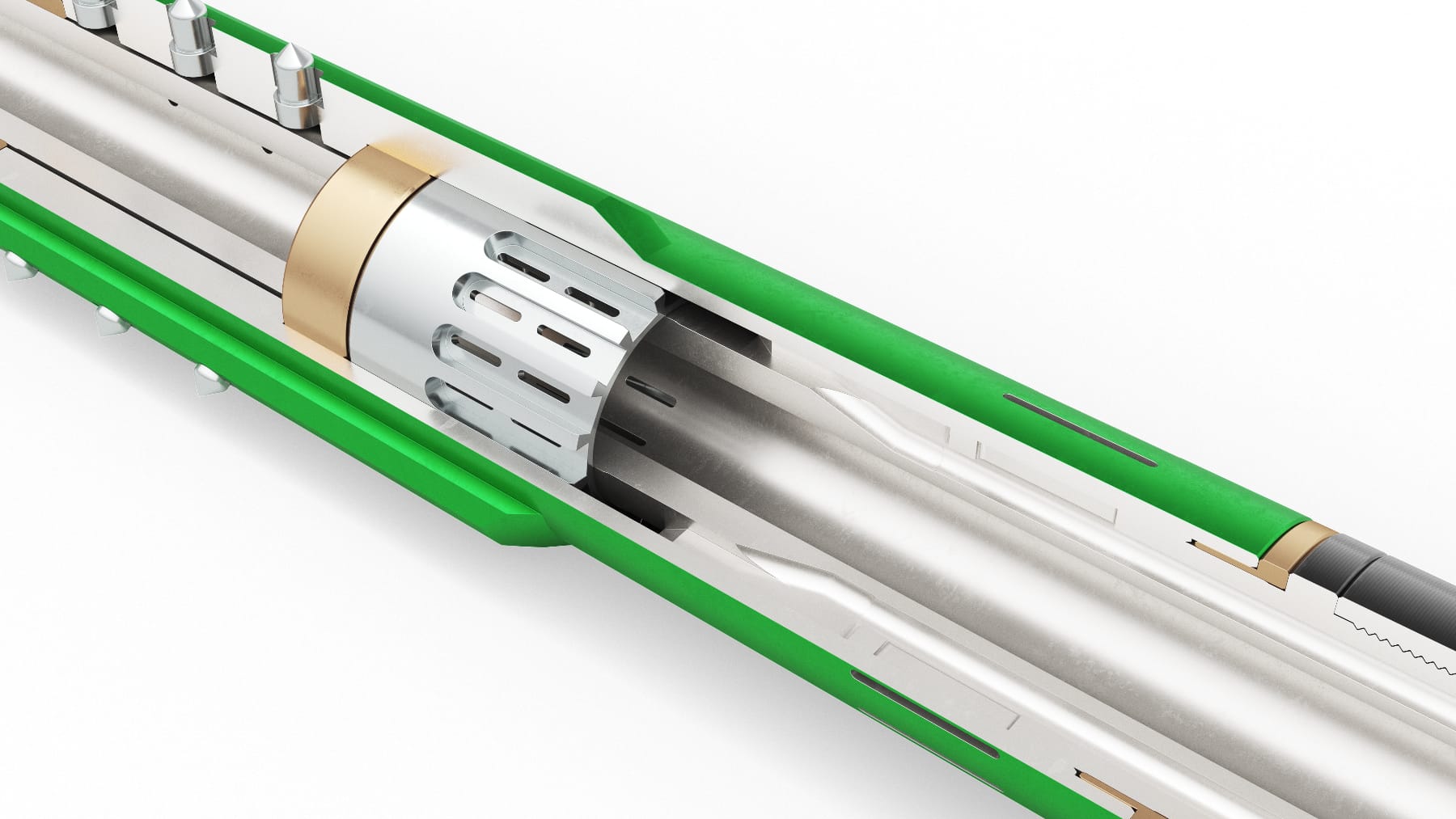

Improved Hydraulics

- Reduced nozzle housing footprint

- Improved port location flexibility

Steel body

- Sustainable

- Repairable

- Globally available

- Recyclable

Simplified for repair

- Reduced number of unique components

- Unified cutter size